AnyCubic recently sent us their gorgeous Photon Mono X 3D printer and Wash and Cure station to try out. This was our first, ahem, exposure to 3D printing with resin, although we* have plenty of experience with filament/FDM 3D printers. Rest assured, this review is independent and was not shared with AnyCubic in advance of publication.

We spent a few weeks using AnyCubic’s Photon Mono X, and, overall, we found it to be an excellent product with a few notable downsides, mostly related to the challenges inherent to printing with resin and not the printer itself.

The Upshot: This Printer Is Amazing

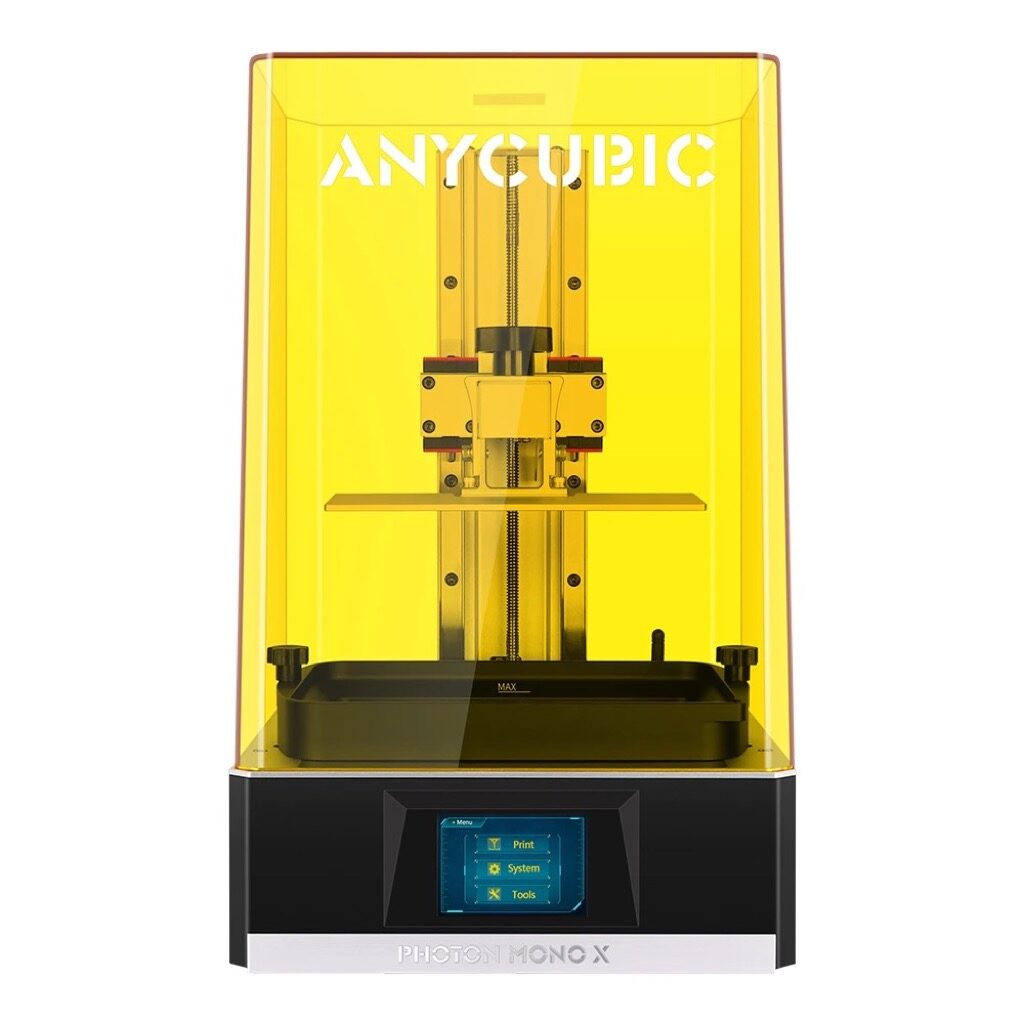

It’s big. It’s beautiful. It’s an MSLA printer. What does that mean? MSLA stands for masked stereolithography. As we noted in our article about how 3D printing works, “MSLA printers use lasers to cure a liquid resin into a solid plastic material. Usually, the object is ‘pulled’ from a vat of resin, forming layer by layer as it rises from the material.”

In other words, it’s magic.

The Caveat: You’ve Got Some Learning (and Cleaning) to Do

It’s going to take some time to get to the point where you’re proficient with the Photon Mono X or any resin printer. Once you know what you’re doing, using this printer is straightforward, but getting there can be frustrating.

We’ve been assured by experts that this experience is universal. It is a rite of passage, similar to getting the first layer to come out right on an FDM printer. The only difference is that if your first layer fails to adhere to the build plate on a resin printer, there’s a lot of messy clean-up involved.

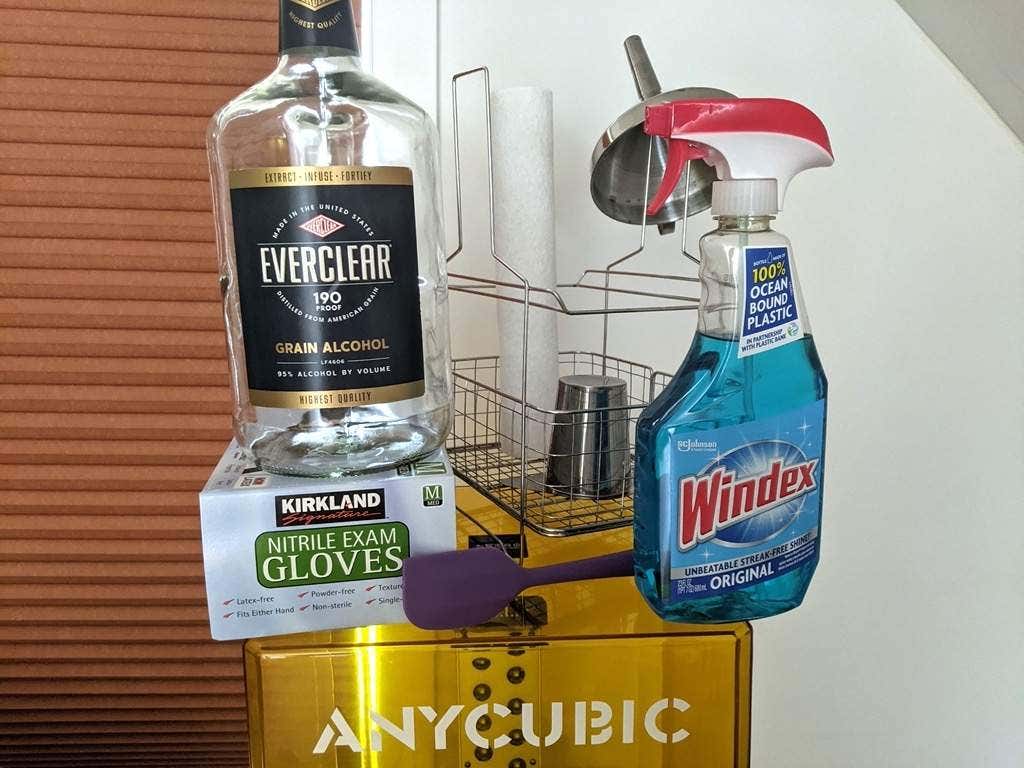

That’s because any time a print fails on a resin printer, you have to clean everything. Since the resin is a toxic material, that means you’ll go through a lot of gloves, masks, paper towels, Windex, and alcohol. (Note: We used Everclear since it’s cheaper than isopropyl, although we’re not sure the cashier at the liquor store believed us.) However, as you improve, there’s less and less clean-up involved.

Resin vs. Filament: What’s the Difference?

A resin printer allows you to print objects with incredibly fine details. If you’re coming from the filament world, the resolution will amaze you. However good you think it will be, it’ll probably be better.

Build Volume & Printing Speed

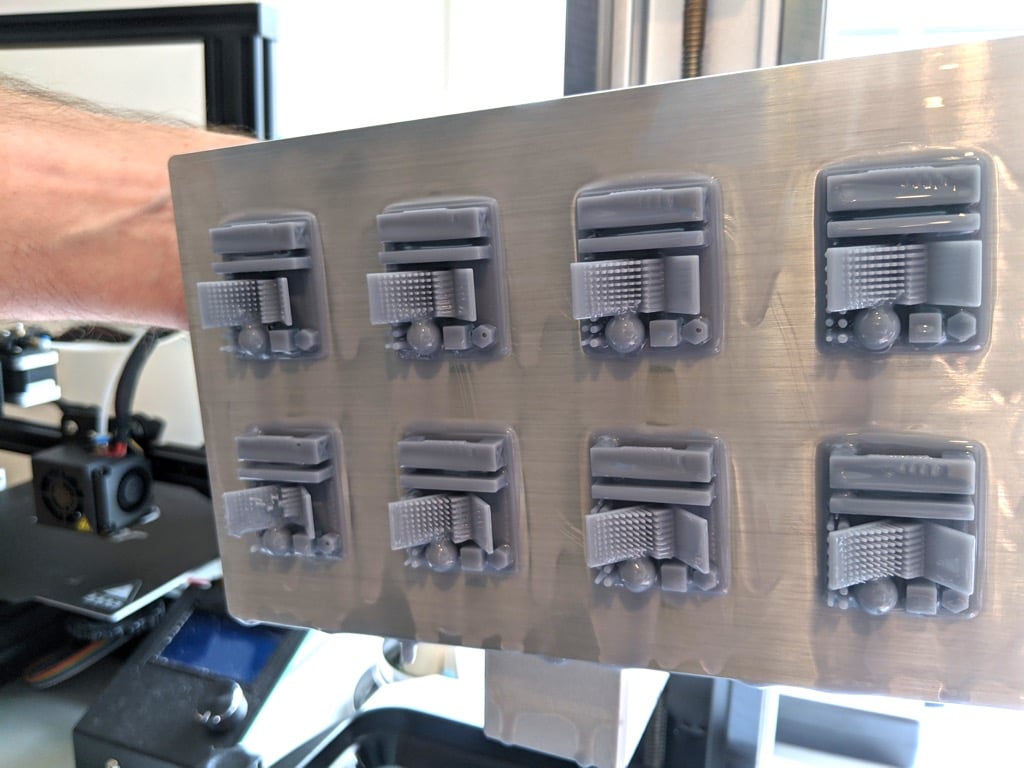

The Photon Mono X has a larger build volume than virtually any other consumer-level MSLA printer on the market today. Moreover, printing time is entirely dependent on the exposure time and the number of layers, not on how much material is cured per layer.

You can cram as much as you want onto the build plate, and it won’t affect your print time.

Product Quality & Safety

The Z-axis rails on the Photon Mono X are no joke. They’re superior to the linear rails on any printer we’ve seen. Linear rails keep your print from wiggling while printing, and there’s no noticeable play on the Photon Mono X. The Z screw is beefy with no visible wobble.

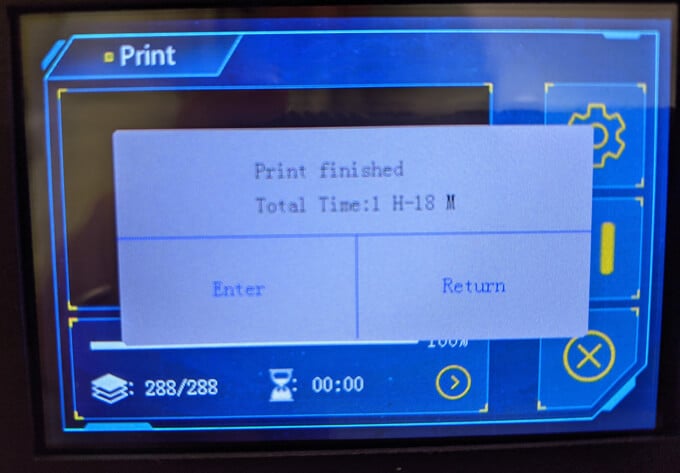

Additionally, the touchscreen is responsive and easy to read, and the menus are intuitive. The overall look is clean and sleek.

The optional safety features are more than adequate to protect your eyes from UV light and protect the resin from sunlight. In fact, we left the resin in the printer for three days next to a window, and none of the resin cured from the sunlight.

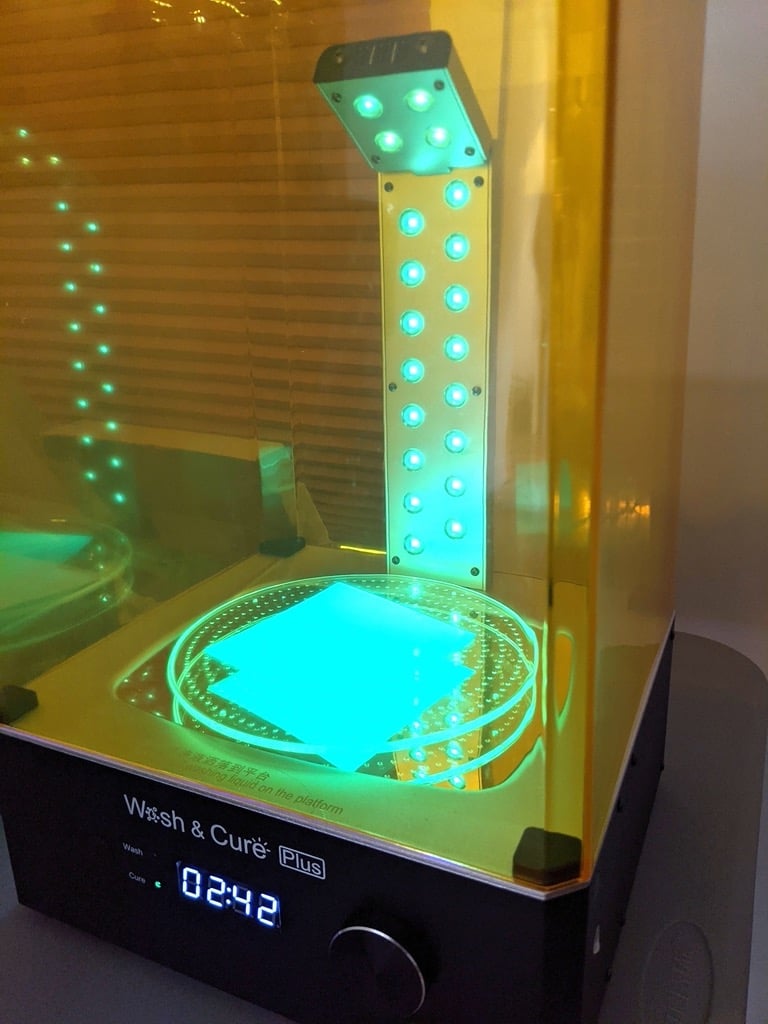

Washing & Curing Your Print

AnyCubic’s wash and cure station perfectly complement the resin printer. They look great together. The wash station has a built-in magnetic stirrer that agitates the cleaning solution, allowing you to clean your print in less than five minutes. It’s almost effortless.

After printing, you can remove the print from the bed or you can put the bed itself into the wash station, alleviating some of the need for cleaning we mentioned above.

Note: You do need a LOT of cleaning fluid, whether that’s alcohol or the cleaning solution of your choice. The cleaning solution goes into a large plastic container with a snap-on top.

To wash, you set the wash timer, hit Go, and you’re done. Be careful handling the uncured print. It will be soft and not fully cured, so it’s easy to deform the print if you’re not careful.

To cure the print, you place it on a carousel that comes with the Wash & Cure station. Optionally, you can adjust the angle of the topmost LEDs to direct light towards the print.

It’s just as easy to cure as it is to wash. Set the timer, press the Start button, and a few minutes later, your print is cured. Enjoy the weird, eerie glow of the print as it’s curing.

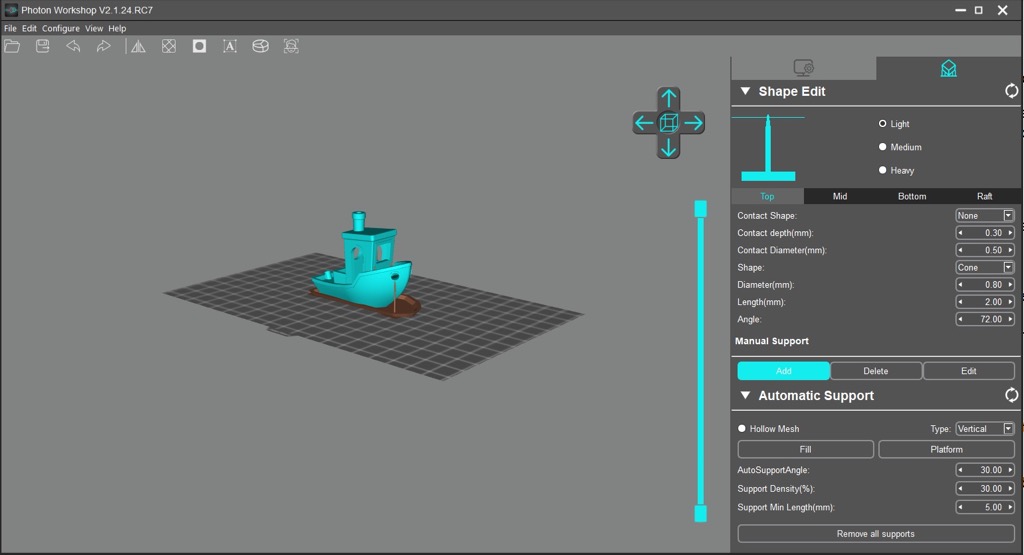

AnyCubic’s PhotonWorkshop

AnyCubic’s slicing software doesn’t feel as polished as Cura or Slic3r, but it does have lots of interesting functionality that, admittedly, we haven’t fully explored. You can add manual or automatic supports, rafts, and drainage holes.

PhotonWorkshop is a little clumsy to navigate and learning how to place supports correctly takes some trial and error. If you don’t adequately support your print, it will fail and then you’ll have to clean the resin vat before your next attempt, so it’s crucial that you learn how supports work.

Transferring files to the Mono X is a snap. Upload a file to a USB drive, and stick it in the printer. Bam. As it prints, you’ll see images on the LCD screen of each layer as it’s being exposed. It’s pretty fun to watch. And, AnyCubic has a phone app you can use to monitor your prints and start them remotely.

Maintaining the Photon Mono X

Regarding maintenance, we wish the resin vat’s pour spout were better designed. Resin doesn’t pour out cleanly, making clean-up more difficult. Moreover, when printing, the resin covers the top of the build plate, not just the bottom, so when it’s time to clean up, you have to clean the resin off of both sides. That’s unfortunate, but we’re uncertain how it could be avoided.

Another complaint: it’s hard to remove the build plate without dripping resin on the machine. You have to do a dance when you remove the build plate. It’s difficult to keep it over the vat so the resin doesn’t drip everywhere. Once you’re consistently getting good prints, this won’t be as much of an issue.

At some point you’ll have to pour the resin back into the container it came in, and you’ll have to clean off the build plate. That process is not as convenient as it could be. Ideally, you’d only have to clean off the bottom and the sides of the build plate. As it is, there are a lot of nooks and crannies that fill with resin, and they all need to be cleaned. It’s kind of like drying tupperware off when it comes out of the dishwasher.

We suspect this is a design tradeoff to maximize the print area while allowing for enough resin for a large print. Furthermore, the printer doesn’t include any funnels or filters, both of which you’ll want to have.

We also tried changing the FEP sheet. The FEP sheet is the film at the bottom of the resin vat. If it gets dirty, scratched, or punctured, it needs to be replaced. As complete beginners to resin printing, we found installing a new FEP sheet to be pretty straightforward. There are a ton of screws to tighten, but following the directions was simple. It was like changing and tuning a snare drum head, and the sound was similar, too!

Final Recommendation

If you’re someone who wants things to just work out of the box with little effort, then perhaps resin printing isn’t for you. That’s not a criticism of the Photon Mono X.

If, on the other hand, you’re someone who will put in the required time to really learn the ins and outs of new technology, then, yes, we absolutely recommend AnyCubic’s Photon Mono X 3D printer. You’re going to love it (eventually). It can print things that would be impossible to print on a filament printer. Plus, it just looks amazing.

* Special thanks to FormerLurker for help in reviewing AnyCubic’s Photon Mono X 3D printer.

Related Posts

- Tribit StormBox 2: The Under $70 Portable Speaker that Stands Out

- ENGWE L20 2.0 Review: The Best Budget-Friendly Foldable E-Bike?

- TopDon TC004 – a Thermal Imaging Camera That Will Give You Predator Vision

- Newyes Portable Wireless Thermal A4 Printer Review

- Eskute Star Folding Fat Tire Electric Bike Review